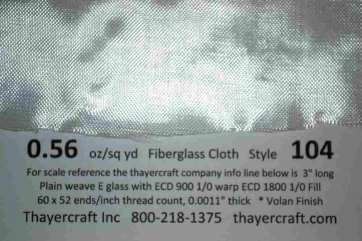

0.56 ounce Style 104 Fiberglass Cloth with Volan Finish+others

0.56oz/sq yd(osy) Fiberglass 104 for Balsa Models

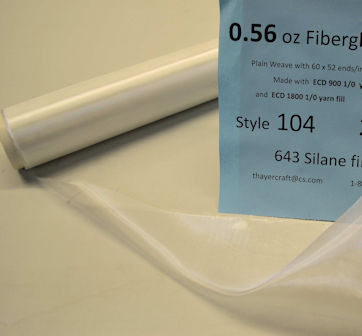

38" wide Style 104 finished in silane for any resin

No stock currently -

except for one roll in the Greige -

meaning still has pva release agents on the yarn

and not suitable for thermoset resins.

All we have is good for silicone rubber

Free shipping to any of the 48 continental United States on all prices and links this page

Rolls of 104 heat cleaned finish

Out of stock

104 in the "Greige" for Silicone Rubber, etc.

CS112 is heat cleaned and washed

CS509 is carmelized

Greige - no finish

Free shipping to any of the 48 continental United States on all prices and links this page

All about Style 104 Fiberglass Cloth

Half ounce, 0.56 ounce per square yard, oz/sq yd(or osy) Style 104 fiberglass cloth is the famous half ounce cloth that's been used for giving a tough skin to balsa model planes for a half century or more. The perfectly shaped true monofilament glass rod filament used in style 104's yarn is just 5 microns in diameter, or less than one tenth the diameter of a human hair. This 5 micron glass rod is carefully drawn through a sophisticated tungsten die at molten glass temperatures to make the yarn for both the warp - length wise down the roll, and the fill - side to side. Double the number of these 5 micron strands are put together to be used as the yarn in the warp as the fill giving it more strength in the warp direction. I don't see it mentioned a lot but it would probably make sense to orient the cloth so the warp yarn will be going down the wing length wise to give more strength wing tip to wing tip. Though we sell fiberglass cloth to many different industries requiring many different finishes from heat cleaned, finishes for more industrial thermosets like melamine, phenolic, polyimide, and lots of fiberglass in the griege - or not finished at all - as a top requirement for the silicone rubber coating industry, one thing you can rely on us for without any doubt is the cloth you buy will be finished as described. I have had customers mentioning something about cloth being "starched" - I don't know what they're talking about and I've been selling fiberglass cloth since 1976 - unless somebody got some cloth somewhere that wasn't finished and still had the yarn release agents on it which we can talk about also. All the cloth on this page is finished for resins. After the 5 micron glass rod used in the 104 is drawn it is plied together to make the ECD 900 yarn for the warp and the ECD 1800 yarn for the fill. The "E"is electrical as in the composition of the glass, the "C" means the glass drawn was continuous as in the true rod making process and "D" is the filament diameter of 5 microns. You add two zeros to the 900 and the 1800 get the number of yards per pound the yarn weighs. There are 90,000 yards of the yarn used in the warp in style 104 per pound! And 180,000 yards per pound of yarn used in the fill or side to side of the cloth. Though incredibly light the yarn used in the warp is twice the weight of that used in the fill and thus my recommendation for keeping the "warp" orientation in mind when you're thinking about the strength. All style 104 we sell or have ever sold is made in the U.S. Fiberglass cloth made in the US is first woven with yarn that has a release agent like Polyvinyl Alcohol on it so it doesnt break during the weaving. After the cloth is woven, or for any material used with thermosetting resins, this release agent is cooked off and washed removing all the residue. To the bare glass a monolayer, or single molecular layer, a "finish" which can be the chrome based Volan or the Silicone based Silane is added to the surface of the glass to make it so it will form a real bond to whatever resin you're using. And also making it so it will wet out. All the cloth on this page is for epoxy resins. The 504 Volan and the 643 can be used for any resin but mostly commonly Epoxy is used and all the finishes on the 104 on this page are for Epoxy. Volan is one of the oldest finishes that has been put on fiberglass cloth. Volan is also the softest. Silanes were developed for various markets like the circuit board and surf board industry - Silanes are clearer, though you can hardly tell at this level - we always describe the Volan finish as having a greenish tint but really only noticeable on heavier cloth and thicker laminations. All this may be a lot to take in but fiberglass finishes are kind of complicated. The most important thing to know is that we know and we're watching out for you. All the cloth on this page will be good for epoxy resins but the softness, or drape, of the cloth will be effected by the finish so the order of softness will be with 504 Volan the softest, 643 silane almost as soft as the 504 volan and 621 silane a little stiffer - which you may need it to be.