0.73 oz Style 106 Fiberglass Cloth with Silane Finiah - Fiberglass Cloth Supply and Education

0.73 oz Style 106 Fiberglass Cloth with Silane Finiah

Other Specifics > Low stock

0.73oz/sq yd(osy) Fiberglass 106 for Balsa Models

50" wide Style 106 finished in silane for EPOXY resin

10 yard rolls on 2" pvc pipe - all we have left in stock

FREE ground shipping to the 48 Continental United States

out again - we'll move this back up to it's

normal spot if more comes in

All about Style 106 Fiberglass Cloth

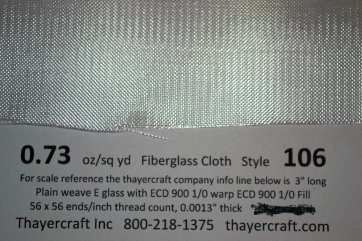

3/4 ounce, 0.73 ounces per square yard, oz/sq yd(or osy) Style 106 fiberglass cloth is slightly heavier and more balanced than 104. Like 104 the true monofilament glass rod filament used in style 106's yarn is 5 microns in diameter This 5 micron glass rod is carefully drawn through a sophisticated tungsten die at molten glass temperatures to make the yarn for both the warp - length wise down the roll, and the fill - side to side. Differing from 104, 106 has the same number of these 5 micron strands put together for the yarn in both the warp and the fill Though we sell fiberglass cloth to many different industries requiring many different finishes from heat cleaned, finishes for more industrial thermosets like melamine, phenolic, polyimide, and lots of fiberglass in the griege - or not finished at all - as a top requirement for the silicone rubber coating industry, one thing you can rely on us for without any doubt is the cloth you buy will be finished as described. I have had customers mentioning something about cloth being "starched" - I don't know what they're talking about and I've been selling fiberglass cloth since 1976 - unless somebody got some cloth somewhere that wasn't finished and still had the yarn release agents on it which we can talk about also. I believe this was something said on a YouTube video - no idea where they got that from. We have 40,000 yards of 106 in the "greige" which still has the PVA release agents on the yarn. Some refer to this as "starch" - not what we sell to the RC industry for compatibility with resins. All the cloth on this page is finished for resins. After the 5 micron glass rod used in the 106 is drawn it is plied together to make the ECD 900 yarn for both the warp and fill. The "E"is electrical as in the composition of the glass, the "C" means the glass drawn was continuous as in the true rod making process and "D" is the filament diameter of 5 microns. You add two zeros to the 900 to get the 90,000 yards of the yarn used in style 106. All style 106 we sell or have ever sold is made in the U.S. Fiberglass cloth made in the US is first woven with yarn that has a release agent like Polyvinyl Alcohol on it so it doesn't break during the weaving. After the cloth is woven, or for any material used with thermosetting resins, this release agent is cooked off and washed removing all the residue. To the bare glass a monolayer, or single molecular layer, a "finish" which can be the chrome based Volan or the Silicone based Silane is added to the surface of the glass to make it so it will form a real bond to whatever resin you're using. And also making it so it will wet out. All the cloth on this page is for epoxy resins. The 504 Volan and the silane CS307, as well as all the other silane numbers we may have on the 106, can be used for Epoxy. Volan is one of the oldest finishes that has been put on fiberglass cloth. Volan is also the softest. Silanes were developed for various markets like the circuit board and surf board industry - Silanes are clearer, though you can hardly tell at this level - we always describe the Volan finish as having a greenish tint but really only noticeable on heavier cloth and thicker laminations. All this may be a lot to take in but fiberglass finishes are kind of complicated. The most important thing to know is that we know and we're watching out for you. All the cloth on this page will be good for epoxy resins but Volan is always considered to be softer and good for any resin - if in case you're using something other than epoxy.

FREE ground shipping to the 48 Continental United States

Instead of trying to get the most money we can we structure our prices

as cheap as we can. Three main things effecting those prices are the supply

of the cloth, the cost of re-rolling it to smaller rolls and the shipping.

We ship most rolls UPS. But with all the government regulations,and

now with CV19, shipping rates are a substantial part of the cost of the

rolls you buy. We are continually improving our packaging processes,

not only so you get the material clean, nice and secure with no wrinkles,

no tape on the cloth itself, but to make it lighter and lighter and reduce that

third big cost - and as we do will pass along to you - the valued customer.